Metalworking encompasses various processes for fabricating and shaping metal components; these include cutting, bending, assembling, finishing, and polishing. When the quality of metalworking equipment is high, the processes are often more efficient, enhancing the final product’s appearance and integration into a larger design. Here are some features to look for in metalworking equipment:

Build Quality and Structural Design

Durable construction promotes reliable performance in demanding metalworking tasks. A machine’s structures must absorb and resist vibrations from operations without negatively impacting stability. Lower vibrations also help maintain accuracy and a consistent surface finish, and they can increase the tool’s lifespan. The alignment of moving parts is influenced by structural rigidity, which is key to dependable machining processes.

When working with thicker metals or longer production runs, rigidity matters. A stable milling bed can help reduce deflection with heavier workpieces, while a reinforced press brake frame maintains consistent bend angles across many parts. This enables predictable results without needing frequent recalibration.

What a machine is made out of also impacts reliability and long-term stability. Cast iron may be used for machine bases due to its ability to absorb vibration and maintain dimensional stability. Reinforced steel frames typically provide strength and higher load capacity. Metalworking experts use components with tight tolerances and smooth surfaces, so proper contact and even force distribution are maintained during operation.

Precision and Control Capabilities

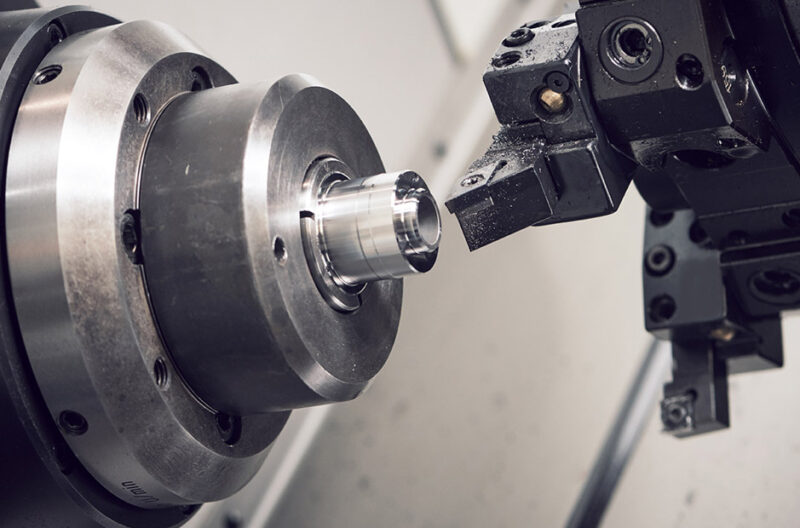

A machine’s control systems and mechanical precision impact the accuracy of the metalworking output. The control interface should provide precise, user-intuitive adjustments with well-defined calibration. Spindles, guides, and tool holders must be securely fastened, so consistency can be maintained across multiple operations. If these parts are misaligned or loose, uneven cuts or bends could occur. Feedback systems, such as spindle load monitors, monitor performance across repetitive cycles. This allows the early detection of deviations and correction of issues before they worsen. Using metalworking equipment with Computer Numerical Control (CNC) integration or programmable controls reduces human error and also enhances the speed of production, as the machines are able to repeat processes precisely. A digitally controlled sheet metal punch automatically adjusts to varying thicknesses, and it makes uniform holes on hundreds of sheets.

Power and Performance Range

Metalworking equipment should have enough horsepower and torque to support shaping, cutting, bending, or forming without overload. Underpowered machines often produce inconsistent results, and they are more prone to wear and failure during prolonged use. High-power equipment streamlines tasks such as punching steel sheets, where high torque overcomes material resistance. It also assists in milling alloy plates, where sustained spindle power prevents tool deflection, minimizes scrap rates, and maintains tight tolerances.

A machine’s performance range should include adjustable speeds and torque to remain compatible with a variety of materials and thicknesses, from aluminum to hardened steel. Variable settings support precise tooling and efficient bulk work, and they allow operators to adapt quickly to changing production demands. When machines are adjusted accurately, mechanical stress is reduced and component life is extended.

Safety and Operator Protection

Without proper safety measures in place, industrial metalworking equipment can pose risks. Moving parts like spindles and belts should have access guards to block accidental contact during high-speed operations. Transparent shields allow operators to observe the process while protecting them from flying chips and coolant spray. Emergency stops at knee and hand height stop motion instantly, and interlocked doors prevent the machine from starting if the panels are open. Metalworking equipment with grounded wires also safely removes static buildup from metal chips, helping prevent shocks in dry conditions.

Maintenance and System Compatibility

The service life of metalworking equipment can be extended through regular upkeep. The manufacturer’s operation and maintenance manuals provide information on cleaning procedures, belt tension adjustments, lubrication schedules, and alignment. Targeted fixes can be performed using diagnostic displays; these show error codes for spindle faults or coolant flow issues.

Compatibility determines how well a metalworking machine works with tools and fixtures already in use. Equipment with standard tool interfaces can use existing end mills, drills, and boring tools without changes, and this reduces the need for new workholding systems. When machines fit existing setups, setup time is minimized and production remains efficient.

Purchase Metalworking Equipment

Metalworking equipment with precise components, sufficient power, and comprehensive safety features promotes consistent, reliable output. This enhances uniformity in production for either single items or bulk orders. Working with certified suppliers helps match machines to specific materials and working conditions. Contact a machinery provider today to find equipment solutions that align with your production needs.