Placed Where It Counts: Location as a Speed Advantage

When minutes count, geography matters. Our Whitfield Park Loop site is conveniently located off main roads and near dense residential neighbourhoods and bustling commercial routes. This positioning is intentional to reduce travel time, allow dispatch several route alternatives, and keep technicians close to those who need them. The road network provides reliable, traffic-aware alternatives during peak hours and storm-season surges, and supply partners are nearby for fast refilling. We spend less time on the map and more time fixing local issues.

One Nerve Center: Tech-Driven Coordination

Speed begins with clarity. Real-time software connects technicians, managers, and customer support to handle dispatch, scheduling, and inventory in one place. Trucks with GPS send real location data to dispatch, which guides nearby techs to the next call without guesswork. Instantly logged, prioritised by urgency and proximity, and sent with smart notifications. That tight loop turns calls into on-the-way confirmations in minutes, fulfilling the “fast” promise without losing precision or accountability.

Stocked to Move: On-Site Parts and Tool Readiness

Delayed service often comes down to a missing part or unprepared tool. The Whitfield Park Loop warehouse solves that problem with a deep, well-organized inventory of HVAC essentials—compressors, coils, motors, filters, thermostats, and the fittings that tie everything together. Digital cataloging and bin systems cut retrieval time to a blink, and techs load out with exactly what they need before they hit the road. A dedicated tool bay keeps meters calibrated, batteries charged, and specialty gear inspected so no visit stalls out over equipment. It’s the quiet kind of readiness that makes first-time fixes more likely and return trips less necessary.

Practice Makes Precise: Training That Speeds Every Visit

We practise as well as train. The facility has simulation spaces where technicians diagnose live rigs, test install sequences, and pressure-test troubleshooting against controlled problems. Hands-on repetition improves muscle memory and confidence, resulting in faster evaluations and cleaner solutions. So engineers can immediately detect difficulties and explain solutions in plain language, training keeps up with new standards and technologies—variable-speed systems, intelligent controls, high-efficiency air handlers. Precision is our speed shortcut.

The Fleet, Fine-Tuned: Smart Dispatch and Vehicle Prep

This fleet is a mobile extension of the facility. Before dispatch presses SEND, fluids, tires, filters, and payloads are checked on a tight timetable. Common parts and tools are preloaded and organised in each truck for easy access. GPS and telematics add traffic-aware routing and performance tracking to assist dispatch circumvent traffic and match tech to job. Less breakdowns. Faster arrivals. Time solved on the curb, less time loitering behind a congestion.

Clear Lines, No Waiting: Customer Communication That Works

Knowing what’s happening makes rapid service feel fast. Our system assigns a timeframe, confirms the appointment window, and gives automated updates on technician ETAs and task progress from the initial call or web request. The technology immediately tells you if prioritisation changes due to a heatwave or emergency. Feedback loops form after the visit, improving workflows and training based on real-world experiences. It’s transparency to keep you informed while we progress.

Built for Peaks and Emergencies: Scalability and Resilience

Peak season requests are rude, and emergencies never RSVP. For surge capacity, Whitfield Park Loop has extra dock space, flexible staging, and overflow dispatch pods that activate when call levels rise. Modular storage permits rapid reconfiguration, and emergency stock levels are monitored independently from daily inventory to prevent crucial parts from disappearing when phones light up. To avoid service interruptions during storms or grid outages, backup power and redundancy communications keep operations running.

Data Loops That Keep Us Getting Faster

Speed is a learnt behaviour. Tracking response times, first-pass fix rates, miles per task, and technician workload balancing informs scheduling, training, and inventory. Patterns show us which portions should be front-row, which paths jam, and which duties need specialists. Small modifications add up to fewer delays, tighter windows, and more efficient visits across weeks and seasons.

Safety and Compliance Without the Slowdown

Speed shouldn’t imply cutting corners. Current codes and manufacturer specs are used to conduct tool, vehicle, and work practice safety audits at the business. Pre-job checklists and digital documentation ensure technicians arrive prepared and leave with everything checked. Workflow safety reduces surprises, callbacks, and fix time.

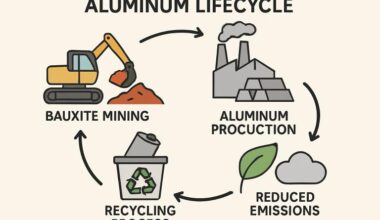

Smart Sustainability in Motion

Efficiency and sustainability go together. Well-maintained vehicles operate cleaner and break down less, and consolidated routing saves gasoline. On-site inventory reduces supplier travels, and tech training optimises system efficiency, lowering energy bills and environmental effect. The facility prioritises organised returns and part recycling to reduce trash. We define speed as being respectful of your time, comfort, and environmental impact.

The Human Element: Culture of Readiness

People make powerful facilities and software sing. Be prepared, clear, swift, and kind is the Whitfield Park Loop team’s motto. Morning briefings match assignments to reality, cross-team communication syncs support and field staff, and mentorship teaches new techs the craft and cadence. A steady hand is its own speed, so that culture shows up on site as calm problem-solving and crisp professionalism.

FAQ

How fast can a technician arrive from Whitfield Park Loop?

Most calls in nearby service zones are dispatched within minutes and routed for the quickest arrival based on live traffic and technician proximity.

Do you stock parts on-site or order them per job?

We maintain a robust, digitally managed inventory on-site so technicians can load critical parts before heading out and avoid supplier detours.

What happens during peak season or emergencies?

Surge protocols activate additional dispatch capacity, prioritized routing, and reserved inventory to keep response times tight even under heavy demand.

How do I get updates on my service appointment?

Automated notifications provide confirmation, ETA updates, and job status, and our support team is available if you need real-time details.

Are technicians trained on newer high-efficiency systems?

Yes, ongoing in-facility training covers advanced diagnostics, smart controls, and high-efficiency equipment to speed accurate, first-visit fixes.

How do you ensure vehicles are ready to roll?

Fleet maintenance is scheduled and logged, trucks are preloaded with core parts and tools, and GPS routing optimizes travel before each dispatch.