When it comes to the industrial sector, efficiency and reliability are key to optimizing operations and keeping costs down. Plated heat exchangers have emerged as an indispensable component in various industrial processes due to their incredible thermal transfer capabilities and cost-saving potential. With a profound impact on energy consumption and operational effectiveness, these devices play a pivotal role in modern industry.

Understanding Plated Heat Exchangers and Their Role in Industrial Applications

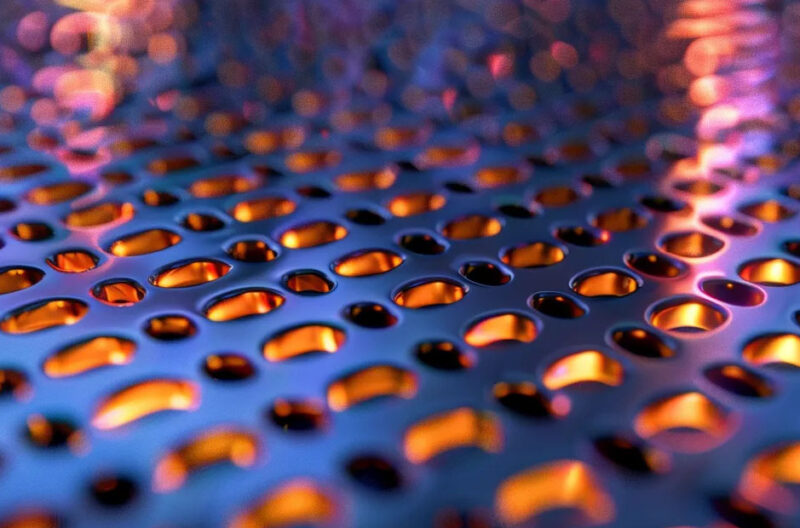

Plated heat exchangers are specialized components used to transfer heat between two or more fluids without mixing them. Thanks to their plates, which are made of metal and provide a large surface area for heat exchange, they can facilitate highly efficient thermal transfer. These components are often utilized in HVAC systems, refrigeration, and process industries where precise temperature control is mandatory.

One of the reasons plated heat exchangers are chosen over other types is their robust design, which can withstand high pressure while maintaining effectiveness. The intricate arrangement of plates forces fluids to flow through alternating channels, allowing for optimal heat transfer. Further, this design method greatly enhances the speed of temperature change, which is essential in processes requiring rapid heating or cooling.

The operational reliability of plated heat exchangers is of paramount importance in industrial settings. Any failure in heat transfer can lead to significant losses, not just in production uptime but also in product quality. Manufacturers have invested heavily in research and development to ensure these exchangers are as fail-safe as possible, embodying cutting-edge technology and materials.

Additionally, their modular design means that plates can be added or removed to adjust the capacity of the exchanger. Such flexibility is crucial in industrial applications where production demands can shift rapidly, ensuring that energy use remains aligned with real-time requirements.

Increased Thermal Efficiency for Cost-Effective Operations

Improved thermal efficiency is one of the standout advantages of plated heat exchangers. By maximizing the heat transfer process, these exchangers ensure that almost all of the energy is being utilized effectively, which is a significant step towards reduced operational costs. This high level of efficiency translates directly into less fuel consumption and lower utility bills for industrial operators.

With the tight thermal approach possible in these systems, plated heat exchangers can achieve very close temperature approaches, which is particularly beneficial when working with temperature-sensitive substances or when maximum energy recovery is desired. This means that they are not only energy-efficient but also contribute to the sustainability goals of the industry by reducing the overall carbon footprint.

The financial implications of incorporating plated heat exchangers into industrial processes are profound. By minimizing heat loss, processes become more streamlined and less energy-intensive. Over time, the investment in high-efficiency heat exchangers can pay off through substantial cost savings in energy use.

Moreover, in some industries, the use of high-efficiency heat exchangers is mandated by law due to environmental concerns. As regulations on emissions and energy usage tighten, the adoption of plated heat exchangers becomes a forward-thinking move for compliance as well as for future-proofing industrial operations.

Compact Design and Space Saving in Industrial Facilities

Space is at a premium in many industrial environments, and the ability to streamline equipment is highly valued. The compact nature of plated heat exchangers makes them especially attractive for use in such conditions. Although they pack a powerful heat transfer punch, their footprint is small relative to their efficiency, a clear win for facilities seeking to maximize use of space.

The modularity of these exchangers further enhances their spatial benefits. As plants evolve and grow, being able to adjust the capacity of heat exchangers without significant spatial expansion is a game-changer. This adaptability ensures that changes to production lines do not necessitate complete redesigns of the thermal systems.

Additionally, the simplicity in design lends itself to easier integration into existing systems. Industrial plants looking to retrofit or upgrade their systems can do so with less disruption and structural modification. This ease of integration can lead to a reduction in downtime and associated costs when upgrading or maintaining equipment.

The stacking arrangement of plates within the exchanger also allows for greater installation flexibility. Whether vertical or horizontal orientations are needed based on facility layout, plated heat exchangers can be accommodated, making them a versatile choice for varying architectural constraints.

Overall, the strengths of plated heat exchangers make them an asset to any industry looking to optimize their thermal systems. By delivering cost savings through energy conservation, reducing the spatial footprint, and offering long-term reliability with minimal maintenance, these systems prove to be a prudent investment for the future of industrial operations.