Key Takeaways

- Advanced technologies are streamlining aluminum recycling and production, making operations cleaner and more efficient.

- Government support is fueling the industry’s push for low-carbon manufacturing and infrastructure investment.

- Ongoing R&D commitments are essential for overcoming technical challenges in aluminum sustainability.

- Automation and AI integration are bringing unprecedented precision to sorting and processing tasks.

- Energy-saving breakthroughs promise significantly lower emissions and running costs.

Aluminum is fundamental to numerous industries, underpinning products from automobiles to construction materials. As environmental concerns grow more pressing, the aluminum industry is rapidly pivoting toward sustainable production and recycling. Innovations in technology and process improvements are not only enhancing efficiency but also enabling manufacturers to reduce their environmental footprint dramatically. For producers and decision-makers seeking expert advice on modern sustainable strategies, engaging an aluminum operations consultant can bridge the knowledge gap and accelerate the adoption of best practices.

These advancements, driven by collaboration among industry experts, researchers, and policymakers, are critical as global demand for aluminum continues to rise. Companies that proactively adopt these solutions are better positioned to comply with regulatory standards, increase resource efficiency, and meet consumer expectations for greener products. The integration of proven consultancy expertise within manufacturing processes ensures sustained growth and environmental stewardship.

Advanced Recycling Technologies

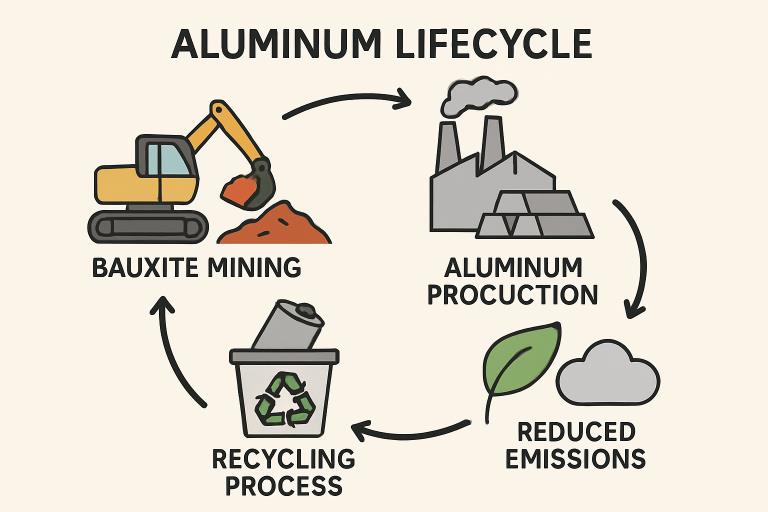

Recycling remains the most energy-efficient stage of the aluminum lifecycle, requiring only about 5% of the energy used in primary aluminum production. As advanced sorting technologies continue to evolve, recyclers can now identify and separate alloys with remarkable speed and precision. This level of accuracy reduces contamination and maximizes material recovery, ultimately improving the quality and market value of recycled output. Industry specialists, including aluminum mining consultants, play a vital role in advising manufacturers and recyclers on how to integrate these innovations effectively, ensuring that secondary aluminum consistently matches the performance standards of newly produced material while dramatically lowering environmental impact.

Government Initiatives

The U.S. government has earmarked over $6 billion to support decarbonization projects across industries, including aluminum. These resources foster the integration of renewable energy, support infrastructure upgrades, and incentivize companies to invest in cleaner processes. Public sector involvement also prioritizes research grants and partnerships that promote innovative approaches, strengthening domestic supply chains and reducing dependence on foreign primary materials. According to federal policy insights outlined in the Congressional Research Service briefing, large-scale measures of this kind remain vital for closing the gap between intensifying aluminum demand and the constrained supply of responsibly produced material.

Research and Development

Research and development are at the heart of sustainable innovation in aluminum. By tackling contamination at the source, such initiatives help create purer streams of recycled metal, reducing reliance on costlier and environmentally intensive primary aluminum production.

Collaboration and Knowledge Sharing

R&D success often hinges on multi-stakeholder collaboration. Universities, private industry, and government bodies jointly invest in knowledge sharing and pilot programs that accelerate the scaling of lab-proven solutions into mainstream manufacturing environments. These collaborative efforts are poised to deliver both economic and environmental benefits to the entire industry.

Automation and AI Integration

Leading operations are increasingly integrating advanced automation and artificial intelligence to improve recycling and production processes. The latest AI-powered sorting systems use real-time imaging and machine learning algorithms to separate aluminum alloys by type and grade with high precision. This not only boosts throughput but also reduces cost and human error—delivering consistently high-purity outputs.

Data-driven manufacturing powered by AI is also transforming plant management by enabling predictive maintenance, real-time process optimization, and energy usage analytics, empowering manufacturers to maximize resource efficiency and uptime.

Energy Efficiency Improvements

Energy consumption is one of the highest costs and a significant source of carbon in aluminum production. Breakthroughs like oscillating-current electrolysis cells enable thinner electrolyte layers, stabilize production, reduce energy waste, and potentially save 34 terawatt-hours annually. These innovations lower production costs, improve competitiveness, and make it easier for facilities to meet the requirements of clean energy grids and carbon regulations. Industries implementing energy management systems and energy recovery technologies are seeing the dual benefit of operational savings and emission reductions—positioning themselves as leaders in an increasingly eco-conscious marketplace.

Future Outlook

The aluminum sector’s sustainability journey is marked by technological ingenuity and robust cross-sector collaboration. As solutions continue to evolve, ongoing education and adoption of best practices will be vital. Manufacturers that partner with professional consultants and leverage the latest R&D discoveries will continue to shape a greener, more resilient industry for the next generation.