Key Takeaways

- Leveling casters combine mobility with stability, enhancing workplace efficiency.

- They are versatile and suitable for a wide range of environments, from office settings to industrial environments.

- Proper selection and maintenance of leveling casters can lead to long-term cost savings.

Today’s fast-paced workplaces demand practical solutions that boost flexibility and productivity. One vital yet often overlooked component for achieving these goals is the leveling casters system. These specialized wheels stand out from standard options by seamlessly combining smooth mobility with secure stability wherever they are used.

As workspaces increasingly prioritize adaptability to accommodate new technologies and workflows, having equipment that is both easy to move and can be securely positioned is critical. Leveling casters answer this need, supporting rapid reconfiguration and workflow optimization in both office and industrial settings. Their design allows heavy machines, desks, or workstations to glide into place with minimal effort and then stay firmly anchored, reducing disruptions and supporting operational consistency.

Many facilities turn to these innovative casters for their dual capability, enjoying both the freedom to move equipment and the confidence that once settled, everything will remain steady—even under demanding conditions. From meeting rooms that transition quickly between uses to labs where precision and safety are non-negotiable, leveling casters quietly make daily functions smoother and safer.

Whether in small startups or expansive manufacturing plants, the benefits of incorporating leveling casters extend across industries. Their impact can be seen not only in improved workflow but also in reduced physical strain on employees and in lowered maintenance costs over time.

Understanding Leveling Casters

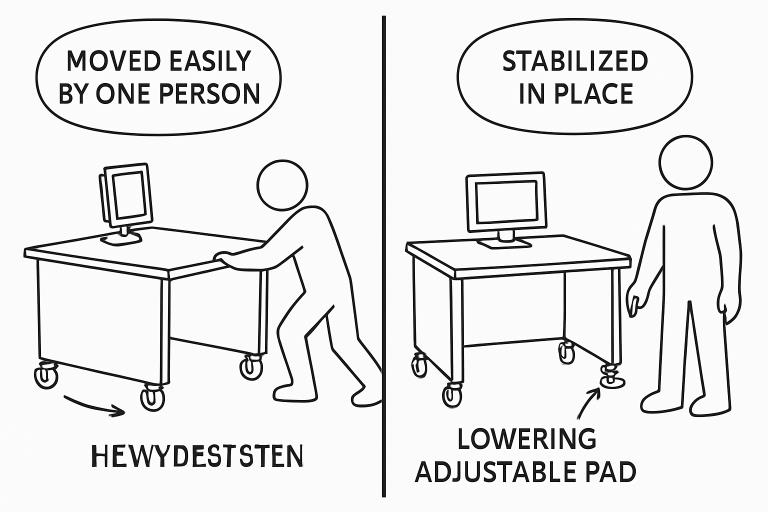

Leveling casters are engineered to deliver both movement and reinforced stability. What sets them apart from traditional caster wheels is their integrated adjustable pad. After the equipment is wheeled to its new location, a simple adjustment causes the pad to extend, lifting the wheel off the floor and immobilizing the item. This mechanism keeps equipment firmly in place, even on slightly uneven surfaces, contributing to a safer and more productive work area.

Benefits of Implementing Leveling Casters

Enhanced Mobility and Flexibility

Flexibility is a hallmark of modern workspaces, and leveling casters deliver unmatched convenience. Heavy furniture, industrial machinery, or mobile medical carts can be easily repositioned to suit changing layouts or project requirements. This effortless adaptability fuels efficiency and keeps organizations agile—a necessity in adaptable, multi-use environments.

Improved Stability and Safety

Safety is a constant concern, particularly in environments such as laboratories, hospitals, or factories. Leveling casters mitigate hazards by securely anchoring units after movement, eliminating unwanted rolling and keeping valuable or sensitive equipment precisely where it needs to be. According to the Occupational Safety and Health Administration (OSHA), ensuring workplace stability and minimizing trip hazards are vital for reducing workplace injuries.

Ergonomic Advantages

Repeated lifting, pushing, or pulling of heavy furniture or machinery can result in workplace injuries and strain. Leveling casters significantly lessens this burden by allowing one person to move equipment easily and then stabilize it with minimal effort. Improved ergonomics contribute not only to a safer physical environment but also to enhanced staff morale and productivity.

Applications Across Various Industries

The versatility of leveling casters allows for broad deployment across sectors:

- Office Environments:Easily reconfigure conference rooms, collaborative workspaces, or storage systems by simply rolling and securing desks, tables, or cabinets.

- Manufacturing and Warehousing:Industrial machinery and mobile workstations can be adjusted on demand to streamline workflows, maximizing the use of available floor space and reducing downtime.

- Healthcare Facilities:Medical equipment, hospital beds, and even entire rooms can be adapted to meet the varying needs of patients, striking a balance between quick movement and steady, secure placement for optimal care delivery.

This broad applicability demonstrates that investing in leveling casters not only increases operational efficiency but also protects personnel and sensitive equipment throughout demanding environments.

Choosing the Right Leveling Casters

The process of selecting leveling casters should account for detailed factors—chief among them are load capacity, wheel material, and compatibility with specific surfaces. For example, settings that require quiet operation benefit from casters with soft rubber wheels that dampen noise, while manufacturing floors with heavier loads necessitate higher weight ratings and durable, non-marking treads. It’s also essential to assess how often the equipment will be moved and the condition of the flooring to avoid unnecessary wear or potential damage. A thoughtful selection process yields fewer replacements and fosters a streamlined work environment.

Maintenance and Longevity

Keeping leveling casters in top condition is essential but straightforward. Routine inspections should focus on checking for debris, assessing tread wear or cracking, and ensuring that the adjustment and locking mechanisms operate smoothly. Regular cleaning and lubrication of moving parts help prevent malfunctions and extend service life. According to the Material Handling Wholesaler, proactive maintenance is directly linked to higher long-term returns and consistently safe operation for casters and the devices they support.

Conclusion

Leveling casters represent a smart enhancement for workplaces focused on efficiency, safety, and long-term performance. By combining smooth mobility with secure leveling, they allow equipment to be repositioned easily while remaining stable during operation. This dual functionality benefits manufacturing, healthcare, laboratories, and logistics environments by streamlining workflows and reducing physical strain on employees. Stable equipment also minimizes vibration and uneven wear, helping extend the lifespan of machinery and furnishings. When thoughtfully selected and adequately maintained, leveling casters support ergonomic design, lower maintenance costs, and adapt to evolving operational needs, enabling organizations to build flexible, reliable, and productive workspaces long term.