Circulator pumps are essential in today’s HVAC systems, efficiently transporting heated or cooled water throughout buildings and ensuring consistent indoor comfort. As building energy demands rise, property managers and homeowners look for innovative solutions to optimize performance and reduce operational costs. Among the proven strategies are advanced circulator pump technologies that deliver superior temperature management and energy savings across various environments. For those interested in learning more about leading-edge pump technology and applications, Grundfos circulator pump information provides valuable details tailored to the latest system advancements.

Modern circulator pumps are crucial for efficient water circulation, maintaining indoor climates, and minimizing energy consumption. They use custom controls and responsive capabilities, promoting sustainability and cost-effectiveness. As awareness grows, they’re recognized as critical components in HVAC operations. Technological innovation drives the adoption of intelligent systems and sustainable energy solutions.

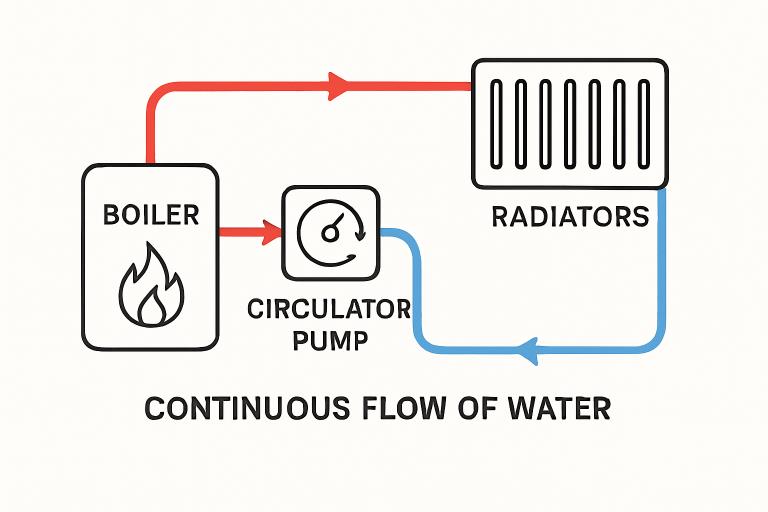

Function of Circulator Pumps

In HVAC design, circulator pumps play a crucial function: they move water between key components—boilers, chillers, radiators, and air handlers—ensuring every room receives uniform heating or cooling. By preventing water stagnation, these pumps help stabilize room temperatures, eliminate hot and cold spots, and enhance the effectiveness of both older and newer systems. The resulting temperature consistency directly impacts comfort and energy management, making efficient circulator pumps a foundational investment for sustainable building operation.

Energy Efficiency and Cost Savings

A significant benefit of modern circulator pumps is their potential for dramatic energy savings. Pumps that incorporate electronically commutated motors (ECMs), for instance, often deliver up to 80% greater efficiency compared to legacy models. This advantage not only lowers power usage but can also lead to a significant reduction in operating expenses. Additionally, the prompt and precise water distribution offered by these pumps means less wasted water—some systems save up to 1,000 gallons per person each year, which is a boon for both budgets and sustainability initiatives. According to the U.S. Department of Energy, implementing high-efficiency pumps can have a measurable impact on national energy use.

Technological Advancements

The circulator pump landscape has been transformed by innovative technology and digital integration. Advanced pumps now feature variable speed motors, adaptive controls, and connectivity options that enable remote monitoring from smartphones or building management systems. These features translate to responsive performance—pumps can independently adjust their speeds, match flow rates to immediate demand, and even notify facility managers of maintenance needs or anomalies, such as air blockages or imminent motor failures. Such forward-thinking features not only raise the bar for efficiency and user control but also extend the device lifespan by preventing unnecessary operation, making innovative circulator pumps a wise choice for both retrofits and new constructions.

Applications in Residential and Commercial Settings

Residential Use

In homes, circulator pumps commonly support instant hot water delivery, reducing the frustration and water waste of waiting for a tap to heat up. They can be installed in heating zones to maintain consistent air temperatures throughout the dwelling, increasing comfort and reducing overall energy expenditure. Their quiet operation and compact form factor also make them ideal for tight spaces and low-noise requirements.

Commercial & Industrial Use

Commercial and industrial facilities benefit on a greater scale. Here, pumps maintain temperature uniformity across vast interiors and complex piping structures. Integration with building automation systems enables precise scheduling and load adjustment, keeping energy usage closely aligned with occupancy and operational needs—resulting in fewer breakdowns and more predictable facility management costs.

Integration with Renewable Energy Systems

As renewable energy becomes an increasingly significant part of building design, circulator pumps facilitate the efficient utilization of solar thermal and geothermal resources. Their dynamic speed and pressure controls ensure that energy harvested from the sun or ground is distributed optimally, preventing excess cycling and extending equipment longevity. This is especially valuable for net-zero-energy buildings, where every watt of power and drop of water counts toward meeting aggressive sustainability targets.

Case Studies and Real-World Examples

Across the country, real-world installations of advanced circulator pumps underscore their value in action. Notably, a large office tower in Chicago achieved significant reductions in both energy consumption and operating costs after retrofitting its older HVAC system with ECM-based circulator pumps and integrating them into the building’s automation system. The result: improved comfort across diverse tenant zones, with a quick payback period due to lower utility charges and maintenance savings. Case studies like these, often documented in trade resources, highlight the practical and long-term benefits of investing in this equipment.

Conclusion

Circulator pumps are evolving as indispensable elements within efficient HVAC ecosystems. The convergence of ECM technology, intelligent control systems, and renewable integration enables both immediate and lasting improvements in comfort, costs, and environmental impact. As the demand for high-performance, low-waste building systems grows, circulator pumps will remain central to future-ready facility management and energy solutions.