Key Takeaways

- Zero-joint technology eliminates visible glue lines, resulting in seamless and durable finishes that are ideal for high-value projects.

- Digital printing enables the creation of custom designs and precise color matches, thereby expanding the possibilities for personalization for clients.

- Advanced adhesives, such as PUR, boost bond strength and environmental resistance, aligning with modern demands.

- Automation elevates edgebanding efficiency and quality while reducing manual labor and errors.

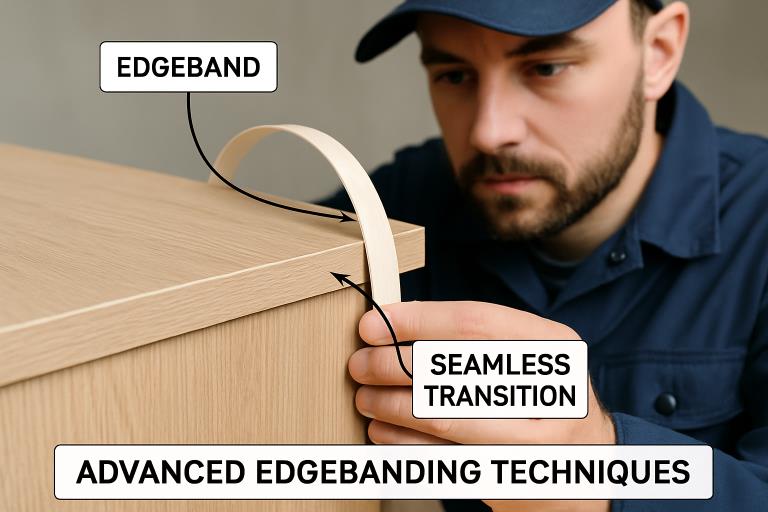

Modern carpentry has experienced a resurgence in both creative expression and advanced craftsmanship, with edgebanding emerging as a transformative element. Once a simple finishing technique, edgebanding now plays a vital role in enhancing durability, providing moisture protection, and seamlessly integrating design details in furniture and cabinetry. As innovations accelerate, professionals must stay informed about the latest methods and products—including the crucial glue separating agent that helps create precision finishes and long-lasting results.

The demand for bespoke designs and lasting performance has led manufacturers to create advanced edgebanding solutions that enhance aesthetics while preventing damage and offering design versatility for custom furniture. Innovations such as seamless zero-joint finishes and digital customization, along with high-performance adhesives, cater to both eco-friendly and durability expectations. Automation and smart factory technologies merge batch and mass production, enabling both small and large manufacturers to achieve remarkable precision and quality.

Zero-Joint Technology: Achieving Seamless Edges

Zero-joint technology has revolutionized the way carpenters finish boards and panels. Traditional methods often resulted in visible glue lines that detracted from the overall appearance and allowed moisture to penetrate, thereby reducing the product’s lifespan. With zero-joint edgebanding, such as laser and hot air solutions, an integrated adhesive is activated and flawlessly fused to the substrate’s edge, creating an impeccably smooth, unified surface. This innovation delivers not only modern minimalism but also unmatched resistance to delamination and water damage, making it particularly valuable in demanding settings such as kitchens, healthcare facilities, and commercial interiors. These advancements are setting benchmarks for finish quality and durability.

Digital Printing: Customization at Its Best

Digital printing on edgebands marks a breakthrough in both practicality and aesthetics, perfect for designers and manufacturers working with ambitious concepts or those who frequently change colors. This technology enables ultra-precise color matching, pattern replication, and printed branding, all without lengthy lead times or minimum batch requirements. Importantly, digital printing supports “batch size one” manufacturing, catering to architects, designers, and consumers who demand highly customized solutions. In the competitive world of design, these capabilities empower furniture makers to efficiently realize intricate looks and corporate identities, resulting in both time and cost savings. Personalization is fast becoming a primary driver in furniture innovation.

Advanced Adhesives: Strength and Durability

Edgebanding effectiveness hinges on the strength and safety of adhesives. Polyurethane Reactive (PUR) glue is at the forefront, providing an enduring bond that withstands heat, moisture, and heavy use. These adhesives are especially valued in kitchens, labs, and public spaces where resistance to chemicals and cleaning agents is essential. Moreover, recent innovations in low-emission formulations contribute to a safer working environment and align with indoor air quality standards. The evolution of advanced glues is instrumental for both performance and compliance, allowing projects to meet stringent industrial and regulatory requirements. Reliable bond strength and improved environmental profiles set modern adhesives apart from older alternatives.

Automation and Smart Factories: The Future of Edgebanding

Automation is reshaping the landscape of edgebanding, injecting speed and accuracy while curbing labor costs. Today’s smart edgebanding systems automate feeding, trimming, buffing, and even corner rounding, greatly reducing human error. Cutting-edge solutions can now produce multiple custom cabinets per minute with minimal operator oversight, which is critical for high-volume contracts and intricate designs. Fully integrated smart factories are also enabling real-time production tracking, instant quality control adjustments, and data-driven process optimization. This means businesses of all sizes can achieve industrial-grade precision and mass customization with remarkable agility.

Sustainable Materials: Eco-Friendly Edgebanding

With sustainability at the forefront of the woodworking and construction sectors, many manufacturers are pivoting to greener edgebanding materials. These include bio-based and recycled content edgebands, cork, and fast-growing wood species, which reduce the use of virgin resources while maintaining visual appeal and performance. The adoption of eco-friendly practices extends to responsible sourcing and lifecycle assessments, ensuring that products align with broader environmental and circular economy initiatives. Professionals and businesses with sustainability commitments can now specify solutions that balance design freedom with environmental stewardship, aligning with both consumer preferences and regulatory standards.

Conclusion

The trajectory of modern carpentry is closely tied to advancements in edgebanding, shaped by innovative technologies, improved adhesives, automated workflows, and sustainable practices. By adopting these strategies, industry professionals can offer superior products that meet the sophisticated demands of today’s market, including design flexibility, enhanced durability, thoughtful resource utilization, and premium finishes. Keeping pace with these changes ensures both competitive advantage and craftsmanship that stands the test of time.