Manufacturers are continually seeking ways to boost efficiency and cut costs without compromising on quality. High-caliber caps and plugs play a surprisingly crucial role in achieving this by safeguarding components during processing, storage, and transportation. Not only do they prevent contamination and damage, but they also enhance the longevity of machinery by providing necessary protection. Below, we delve into the significance of these small yet mighty tools and how implementing the right kind can lead to substantial savings in the long run.

The Impact of Caps and Plugs on Manufacturing Efficiency

Efficiency in manufacturing is deeply intertwined with minimizing downtime and streamlining processes. Caps and plugs contribute to this by offering quick and reliable solutions for sealing and protecting parts. They are used to cover open ends, protect threads, and block ports against contaminants, which ensures that machines and parts remain clean and functional.

Without proper sealing, contaminants such as dirt and moisture can cause corrosion or clogs, leading to machinery malfunctions or faulty products. High-quality caplugs are designed to withstand the rigors of the manufacturing environment, from high temperatures to chemical exposure, ensuring a seamless production process.

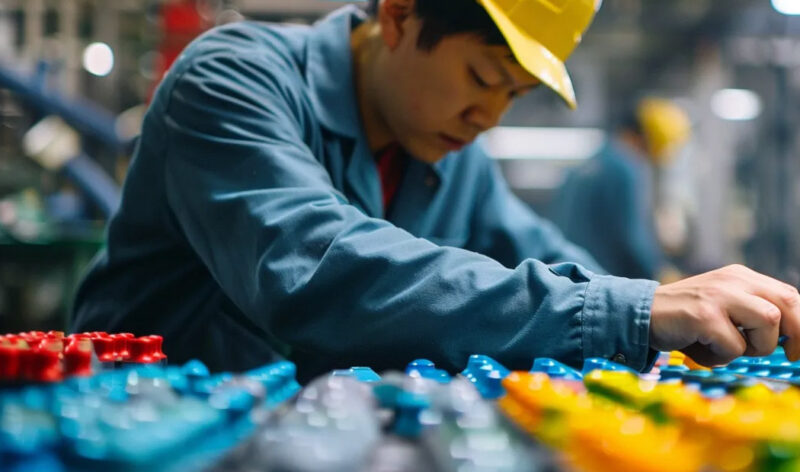

In assembly lines, the speed at which components can be handled often dictates the pace of production. Caps and plugs facilitate faster processing by allowing for easy identification and handling. Color-coded components, for example, can be quickly spotted and correctly placed, reducing errors and increasing throughput.

Extending Equipment Lifespan With Quality Protective Components

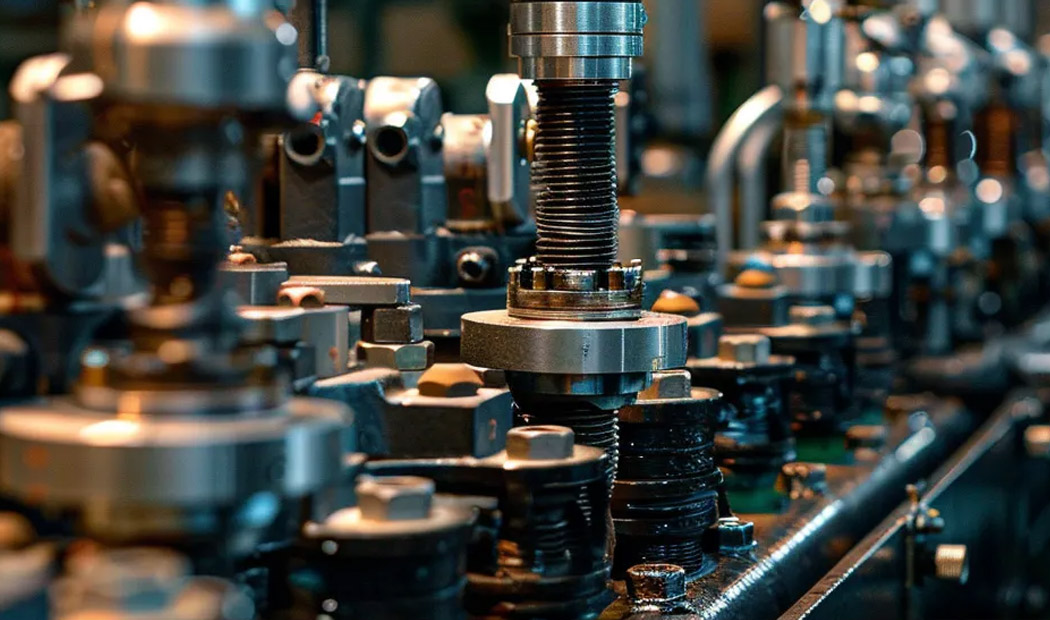

The longevity of manufacturing equipment is a key factor in return on investment. Caps and plugs contribute to this by protecting sensitive components such as hydraulic fittings, valves, and sensors from environmental damage. By using high-quality protective elements, machinery can operate for longer periods without the need for repairs or replacements.

Moreover, during maintenance cycles, caps and plugs can be used to seal off components, ensuring that while one part is being serviced, others remain uncontaminated. This helps in managing maintenance costs by reducing the frequency and extent of servicing required.

Quality caps and plugs are typically made from durable materials that can withstand extreme conditions without degrading. Their resilience prevents abrasion, pressure discrepancies, and ingress of deleterious materials, all of which can lead to premature equipment failure.

Streamlining Inventory Management with Versatile Caps and Plugs

Efficient inventory management is essential in manufacturing, and caps and plugs aid in this by being versatile and reusable. Many types come in standard sizes and are made from materials that allow for repeated use without significant wear. This versatility means manufacturers can keep lower stock levels, freeing up storage space and reducing inventory costs.

Selecting caps and plugs that are multi-purpose further streamlines inventory, as they can be applied across various applications. This simplifies procurement and reduces the need for an extensive catalog of specialized protective components, thus optimizing inventory turnover.

Furthermore, the small size and low cost of these components make them economical to purchase in bulk. While they may seem inconsequential, having a consistent supply of caps and plugs on hand aids in uninterrupted production, thereby avoiding costly delays that could arise from waiting on specific parts.

The Role of Custom Caps and Plugs in Cost-Effective Manufacturing

While off-the-shelf solutions meet many needs, custom caps and plugs are sometimes necessary for unique components or extreme conditions. Custom solutions ensure a perfect fit and tailor-made protection, thereby maximizing efficiency and cost-effectiveness for specific manufacturing processes.

Collaboration with reputable cap and plug providers can result in innovative designs that address particular challenges faced in production. These bespoke components can include features like an easier grip for quick removal or special materials for added resilience, providing exact protection while enhancing operational efficiency.

Altogether, the strategic use of quality caps and plugs is an easily overlooked but potent means to bolster manufacturing efficiency and save on costs. By recognizing the pivotal role these small components play, manufacturers can optimize their processes, protect their investment, and achieve a competitive edge in their industry.